Quality Procedures (QP) Programs

The SSPC QP Programs (now AMPP QP Programs) cover coatings application in a field and shop setting as well as specialty programs for specialized procedures such as nuclear, metallizing, and polymer coatings. We also have an accreditation program for coating inspection companies (QP 5) and an advanced accreditation for organizations based on more stringent standards (QS 1).

QP 1 – Field Coating Application

The QP 1 accreditation is an internationally recognized program that evaluates the practices of industrial painting contractors in key areas of business related to field coating application.

QP 2 – Field Coating Removal

This accreditation is a nationally recognized program that evaluates the capabilities of industrial/marine paint contractors on their ability to safely remove and properly manage hazardous coating material in the field.

QP 3 – Shop Coating Application

The requirements for QP 3 are like those for QP 1, except they are specifically focused on shop coating operations instead of field application.

QP 5 – Inspection Company Accreditation

The QP 5 accreditation program is for coating inspection companies that work in the industrial coating and lining industry.

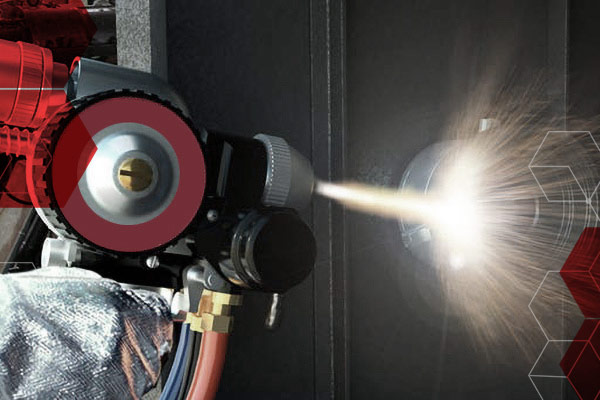

QP 6 – Contractor Metallizing

Used by facility owners or their protective coating specialists or specifying engineers to ensure that contractors hired to perform metallizing work to protect bridge, industrial or marine structures, or miscellaneous metal parts have the primary technical capabilities and organizational structure to do the work.

QP 7 – Contractor Introductory Program

This program’s objective is to determine if a painting contractor has the personnel, organization, qualifications, procedures, knowledge, and capability to produce quality surface preparation and coating application on industrial, marine, or commercial / institutional structures.

QP 8 – Polymer Coatings on Concrete

This accreditation is for facility owners to ensure that contractors hired to install polymer coatings or surfacings on concrete and other cementitious surfaces have the technical capabilities and organizational structure necessary for the work.

QP 9 – Commercial Painting & Coating

This is a nationally recognized accreditation program that evaluates the practices of commercial painting contractors in key areas of business, setting forth the minimum level of service and quality required for today’s coatings industry.

QS 1 – Advanced Quality Management

QS 1 is the standard procedure in the PCCP program that requires participating contractors to implement and document more stringent (ISO 9001-compliant) quality control and record-keeping procedures.

QN 1 – Nuclear Coating Supplement

This supplemental procedure describes a method for evaluating the primary qualifications of industrial coating contractors that perform work in nuclear power plant and shop facilities that coat parts or components for installation in primary containment or other safety-related areas of light-water nuclear power plants.

In-House Training Qualification - AS 3

Accreditation for employer in-house training of personnel for coating application.

3rd Party Training Qualification - AS 3 ITO

Accreditation for training of personnel related to coating application for independent training organizations.

AB 1 Qualification Program – Abrasives

An online list of non-metallic abrasives certified to meet needed requirements to enable quick selection of media for projects.

CAS certification & QP 1 contractor accreditation

The Coating Application Specialist (CAS) Certification Program for industrial painters was established in 2008 in order to strengthen the qualifications of the current workforce and lay the groundwork for development of a strong industrial painter work force for the decades to follow.